A new innovation-packed electric powertrain for Alpine A390

Published on

Alpine A390, Alpine’s first fastback sports car, aims to deliver driving thrills on a par with the A110. To this end, the engineers at Ampere – the Group entity with advanced expertise in electric vehicles and motors – developed a completely new powertrain packed with innovations. Read on to find out more.

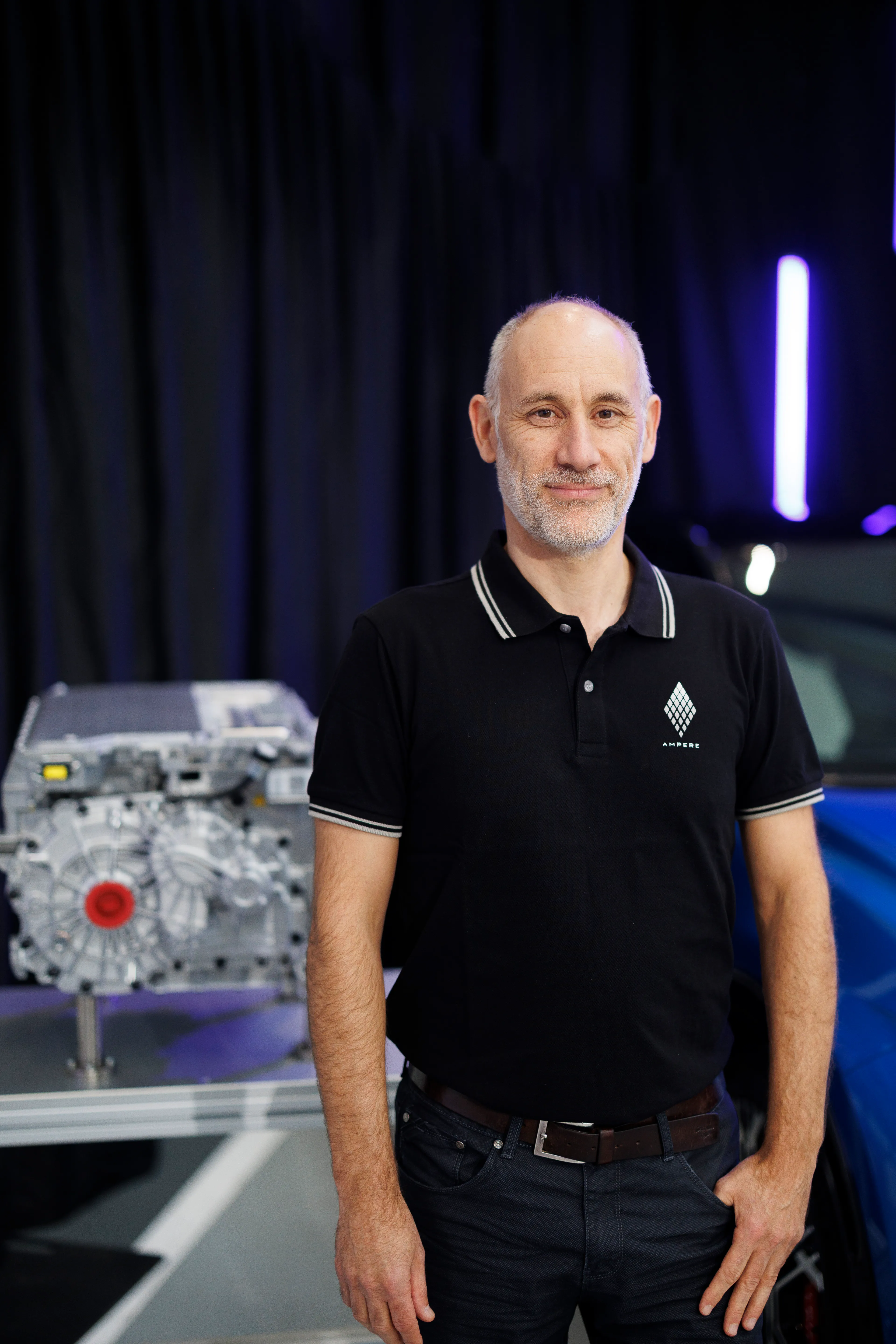

The second model in Alpine's dream garage, Alpine A390 was unveiled on 27 May 2025 in Dieppe. This global premiere marked the reveal of a completely new powertrain designed specifically for Alpine A390. Nicolas Devanne, engineering project manager at Ampere, talked to us about the many innovations seen for the first time at Renault Group.

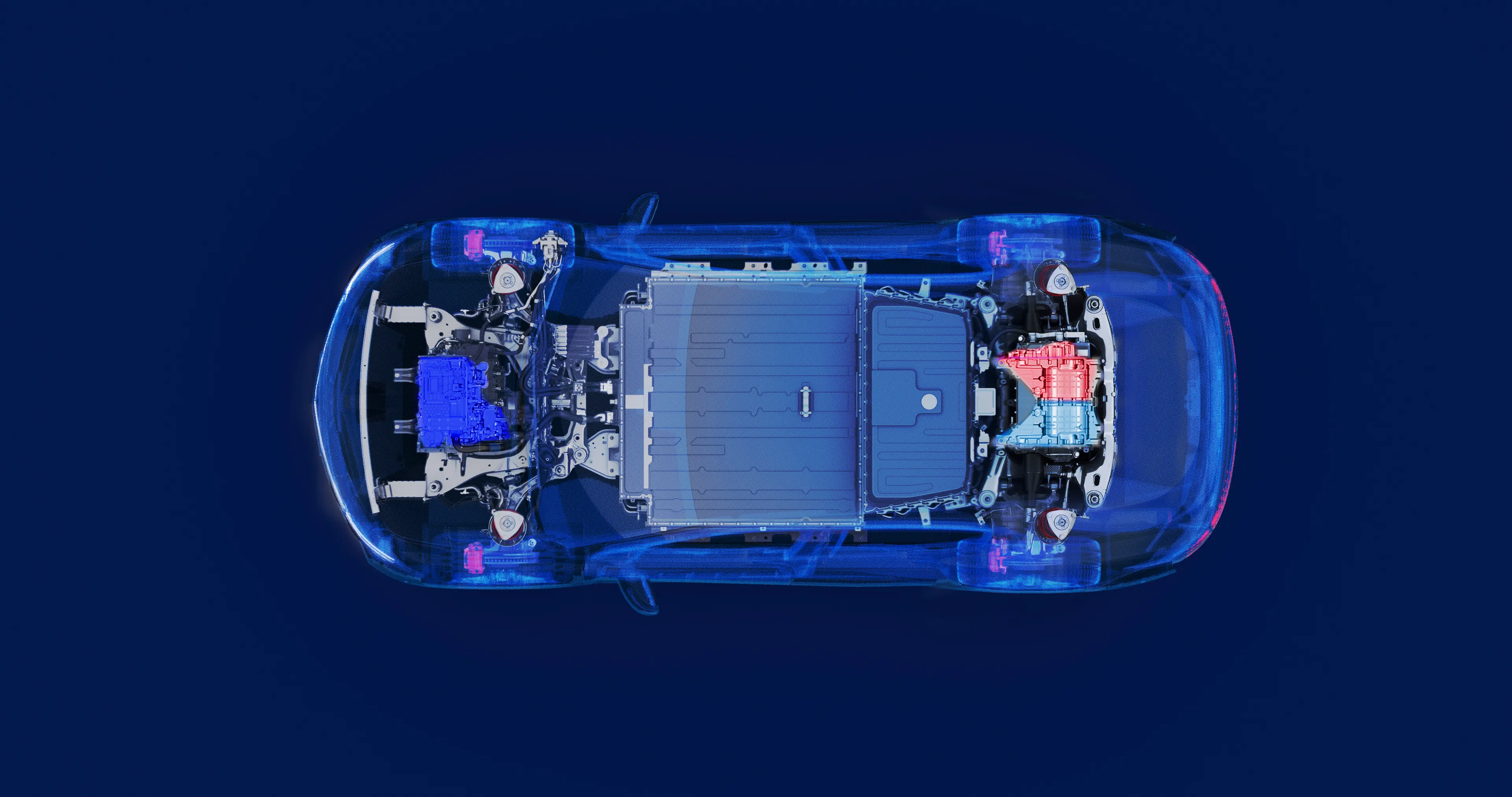

A powertrain of advanced performance comprising three electric motors

Delivering the agility and driving pleasure characteristic of Alpine, Alpine A390 is also a versatile vehicle, able to seat up to five people. At the same time, it turns in an exceptional performance with its new 470 ch powertrain.

“Alpine A390 accelerates from 0 to 100 km/h in under 4 seconds and runs 1,000m from a standing start in 22 seconds. To achieve these figures, we opted for an architecture of innovative design, since the all-electric powertrain is actually made up of three motors! “

Nicolas Devanne

Alpine A390 powertrain project manager

In line with convention, the front axle houses the first electric motor, also found on Alpine A290. To optimise the top speed of A390, the gear ratios have been modified.

The main innovation is on the specially developed aluminium rear cradle, which now houses two motors, each with output of 125 kW.

“This unique configuration makes Alpine A390 the first brand model to feature three motors and all-wheel drive, so that’s four drive wheels, as well as more than 400 horsepower” continues Nicolas.

A true Alpine, a real thrill machine

“Staying true to the brand's DNA, our main priority during the four years it took to develop this powertrain was to reconcile power and agility” explains Nicolas before adding, “Every technical feature on Alpine A390 contributes to its identity as a real sports car, a true Alpine.” Alongside an innovative battery module with a low centre of gravity, the tri-motor architecture offers ideal weight distribution: 51% at the front and 49% at the rear.

To manage the front powertrain and rear motors (each one is dedicated to a rear wheel), the engineers developed a completely new operating principle based on an all-wheel drive system – a first for Alpine. This system also optimises the impressive level of torque transfer (acceleration intensity measured in newton metres written Nm). With output of up to 470 hp and 808 Nm of torque, A390 GTS gains the most potent powertrain ever built by Alpine.

“While Alpine A390 is an all-wheel drive, it is designed to drive like a rear-wheel model” adds Nicolas, keen to reassure Alpine brand customers and fans.

Alpine A390 also achieves impressive cornering efficiency with another major patented innovation unveiled on this model: Alpine Active Torque Vectoring. This ultra-innovative system plays a major role in the driving dynamics of A390 by constantly adjusting torque distribution to the rear wheels through the independent control of each rear motor. Depending on the steering wheel angle and speed, Alpine Active Torque Vectoring responds in the space of milliseconds, correcting the slip difference between the right wheel and left wheel (or vice versa) and adjusting the torque on each rear wheel. This innovation optimises grip, for a safer and more exciting drive.

Motors and powertrain assembled in France

The three Alpine A390 motors are manufactured at the Cléon site. Housed in a workshop of over 3,000 m2, the production line for the new twin-motor unit (internal part number 7DL) mounted on the rear cradle was inaugurated on 23 September.

The Cléon plant has been producing most Renault Group powertrains since 2015. At this time, it began making the electric motors for Renault ZOE, Twingo ZE, Kangoo ZE and Master ZE. Today, the site is part of the Ampere production ecosystem, grouping the ElectriCity complex in northern France, along with the Douai, Maubeuge and Ruitz plants. Cléon produces the motors for Megane E-Tech electric, Scenic E-Tech electric, Alpine A290, Renault 5 E-Tech electric and Renault 4 E-Tech electric.