Ampere ElectriCity, the new leading site for industrial EV excellence located in the Hauts-de-France

Published on

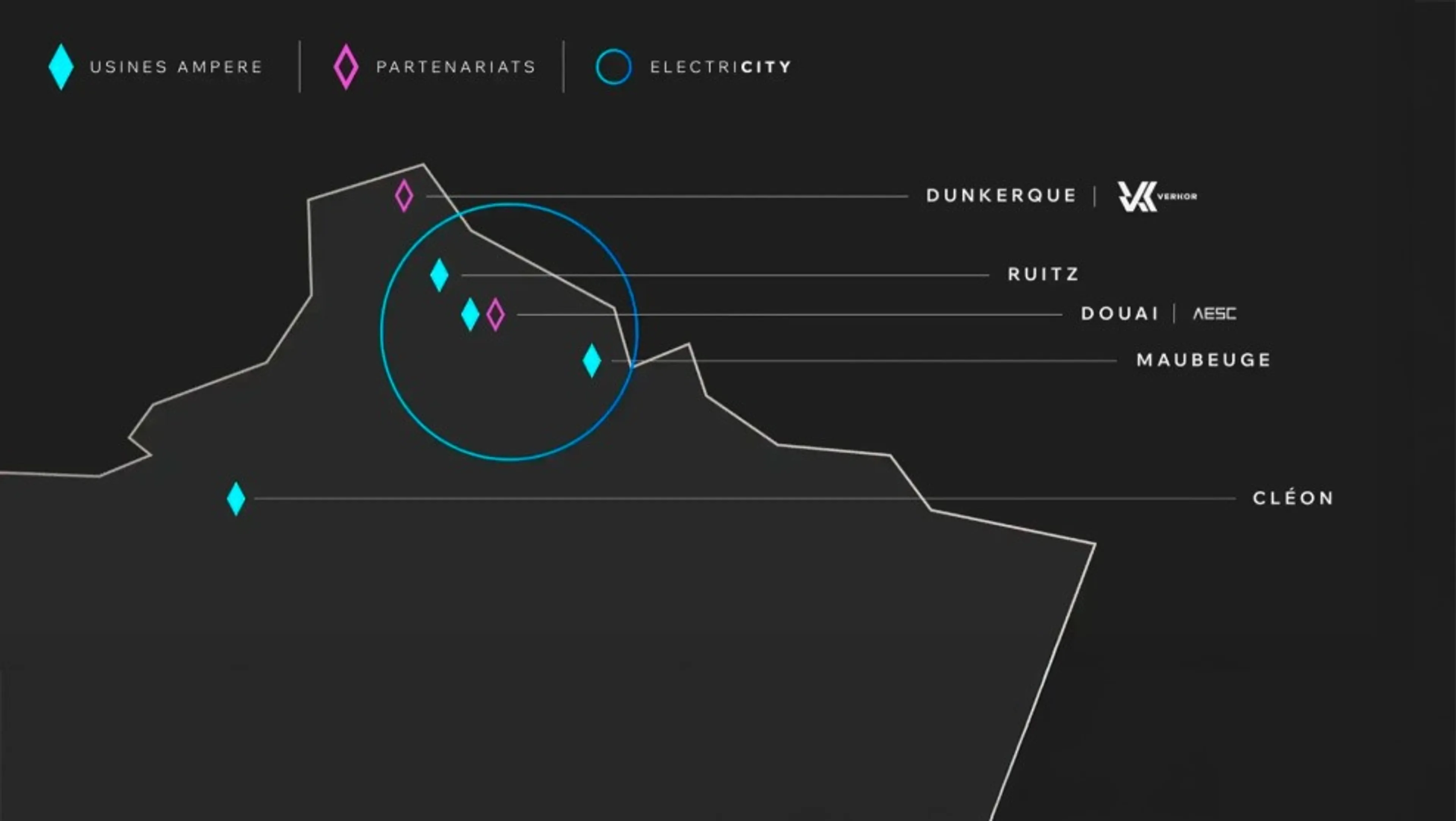

When Renault’s three manufacturing plants in northern France – Douai, Maubeuge, and Ruitz – come together to create the largest and most competitive EV production facility in Europe, you get Ampere ElectriCity! This is an overview of a new leading facility within the Group’s industrial ecosystem.

This is an extraordinary human and industrial adventure that begins in 2022 in the Hauts-de-France. Less than six months after Luca de Meo, Group CEO, announced the creation of a vast EV hub as part of the Renaulution plan, Group and trade union representatives signed an agreement approving the transformation of facilities at Douai, Maubeuge, and Ruitz, representing more than 5,000 employees. More information about this agreement

Called ‘Ampere ElectriCity’, this industrial complex is now the nerve center of Ampere, the Group's entity dedicated to electric vehicles. With the support of the Cléon plant, near Rouen, which supplies, among other things, the engines for the new electric models, the aim of this consolidation is also to bring together a complete ecosystem of suppliers in close proximity in order to innovate and reduce numerous costs for increased competitiveness.

A TRICOLOUR FUTURE FOR EV

Set course for the north of France, where three plants have shared the same passion for the past 50 years: automotives. Here in Douai, Maubeuge, and Ruitz, millions of iconic cars and gearboxes from throughout Renault’s history have rolled out their factory doors. 2021 marks the dawn of a new era. Renault Group is placing France at the heart of its electric strategy. With best practices being shared across sites, a non-negotiable red line built around ‘Made in France’, and new synergies kicking off, everything is geared towards ensuring a high-level competitive edge.

Three years later, the objective is becoming a reality: the two new models manufactured in Douai - Renault 5 E-Tech electric and Scénic E-Tech electric - have received the 'Origine France Garantie' certification* awarded by Bureau Veritas.

*(a certification granted to products whose final assembly is carried out in France and for which at least 50% of the unit production cost, as well as its essential characteristics, are acquired in France)"

THE AMPERE CENTRE OF OPERATIONAL EXCELLENCE

The three Ampere ElectriCity plants in Douai, Maubeuge and Ruitz are historic Group sites now dedicated to the electric future of mobility. The Cléon plant supplies these sites with engines.

Thanks to a brand-new production line, the Douai plant has been manufacturing its first electric vehicle, the Mégane E-Tech Electric, since early 2022. The 100% electric range was later expanded to include the Scénic E-Tech and Renault 5 E-Tech. The battery assembly workshop created within the factory assembles the necessary batteries on-site. More than 550 million euros have been invested in the workshops to accommodate the electric versions and ensure optimal ergonomics at the workstations.

The Maubeuge plant, specialised in making vans, has manufactured three generations of the Kangoo, including the first electric Kangoo launched in 2011, a pioneer and leader in the electric van segment in Europe since its launch. The site also produces commercial vehicles for Daimler (Mercedes Citan) and the Nissan Townstar. Since 2023, these models have also been produced in electric versions.

The Ruitz plant supplies gearboxes, including the DB35 installed across the entire E-Tech range, which has been produced since March 2022. Ruitz is also transitioning to electric, with future production of battery trays (housings containing the battery modules) for electric vehicles manufactured in France, including the Renault 5 E-Tech Electric. To achieve this, a memorandum of understanding for the creation of a joint venture between Renault Group and Minth Group was signed in June 2022.

The Cléon plant manufactures very high-performance electrical and mechanical components. Since 2015, it has produced the electric powertrain for the Renault ZOE, Twingo E-Tech Electric, Kangoo E-Tech Electric, and Master E-Tech Electric. On July 5, 2022, a new electric motor production line, the 'ePT-160kW,' was inaugurated. By 2024, the plant will reach a production capacity of over 1 million electrified engines per year, including 500,000 electric motors and 510,000 hybrid motors.

AN ECOSYSTEM OF PARTNERS

The three Ampere ElectriCity sites are part of an ecosystem open to partners, particularly in the battery sector. The local establishment of Envision in Douai and Verkor in Dunkirk enables collective skills development, shortens the supply chain, and contributes to decarbonizing production. The stated commitment is to achieve net-zero carbon emissions at the Ampere ElectriCity sites by 2025. More information

The future EV battery gigafactory, born of a strategic partnership between Renault Group and Envision, has been under construction near the Douai plant since the summer of 2022 (less than 50 metres apart). Starting in 2025, it will produce state-of-the-art batteries, at a competitive cost, with a smaller carbon footprint for future electric models, such as the Renault 5. More information

French start-up Verkor will work with Renault Group to co-develop high-performance and low-carbon batteries, with production starting in Dunkirk in 2025. More information

Minth Group, one of the world's leading automotive suppliers, has signed a memorandum of understanding for the creation of a joint venture to produce battery trays at the Ruitz factory. More information

1 00% ELECTRIC, AFFORDABLE, AND POPULAR MODELS

To achieve this industrial goal, Ampere can rely on the expertise of its factories. In 2022, the Douai plant produced its first electric vehicle, the Mégane E-Tech Electric, then launched the Scénic E-Tech Electric the following year, and continue in 2024 with the highly anticipated Renault 5 E-Tech Electric. At Maubeuge, the New Kangoo received a facelift in 2021. This site, specialized in van manufacturing, also produces commercial vehicles for Daimler (Mercedes Citan) and Nissan (NV250), and as of 2023, all models are produced in electric versions. The Ruitz plant, a key player in the transition to electric vehicles, is introducing a new activity focused on manufacturing electric components

THE PATH TO EMPLOYMENT

In Hauts-de-France, working for Renault is something to be worn with pride. The Group has been a local name for half a century. Be it in Douai, Maubeuge, or Ruitz, generations of men and women have built up the success and reputation of the factories in which they work. Deeply rooted in the local fabric, Renault Group stands out as the region’s largest automotive employer. With this rapid industrial transformation, Renault Group is contributing to the employment pool.

Ampere ElectriCity is also the story of bringing together an entire ecosystem of research centres, universities, and start-ups to ramp up research and development of innovative technological EV solutions and services, and to train manufacturing teams.

Located in the heart of Europe, at the crossroads between supply and demand, Ampere ElectriCity has everything it needs to become the continent’s leading hub of EV know-how and production across the entire manufacturing value chain.