Le Mans, Renault Group’s chassis expertise hub

Published on

Just a few kilometers from the 24 Hours of Le Mans circuit, one place ensures the safety and handling quality of millions of drivers: Renault Group’s Le Mans site. It is where the chassis of our vehicles are designed, tested and produced. This discreet yet essential activity has spanned generations, constantly adapting to new materials, electronics, digital technologies and now electrification. Mechanical tradition and innovation come together here, supported by a rich heritage within a site that is over a century old.

Le Mans: where the history of automotive chassis took root

When people think of Le Mans, they often picture the legendary 24 Hours circuit. Yet just four kilometers away, another chapter of automotive history has been written for more than a century. Originally specialized in manufacturing wooden body frames, then in mechanical and agricultural activities, the Le Mans site shifted after the war toward a field undergoing major transformation at the time: the chassis. A direction that would gradually become its true hallmark.

“In Le Mans, chassis expertise is expressed as an art of balance between heritage and innovation. Our engineers and technicians shape the connection between the road and the driver, combining mechanical precision, creativity and technological boldness.”

Jean-Luc Bois

Chassis Industrial Director and Director of the Le Mans site

‘We work on something people don’t see but feel immediately.’ This direct way of talking about technique perfectly reflects the spirit of the place: a blend of experience, knowledge-sharing and attention to detail.

Over the past decades, the site has been structured and strengthened around road handling expertise. Engineers, technicians, prototyping, test benches and production teams now share the same buildings. It’s a unique proximity in the automotive world, one that fosters collaboration and accelerates progress.

The chassis, part of Renault Group’s DNA

Renault Group’s Le Mans site supported the acceleration of chassis transformation with the development of new post-war models.

The 1960s saw the emergence of major innovations on the Group’s vehicles, such as:

- the rear axle with torsion bars on the Renault 4, a compact and ingenious solution that offered both comfort and interior space;

- the four disc brakes on the Renault 8, a first for a mass-produced model.

In the 1970s, the Renault 17 became the first Renault equipped with ventilated discs, delivering more efficient and consistent braking.

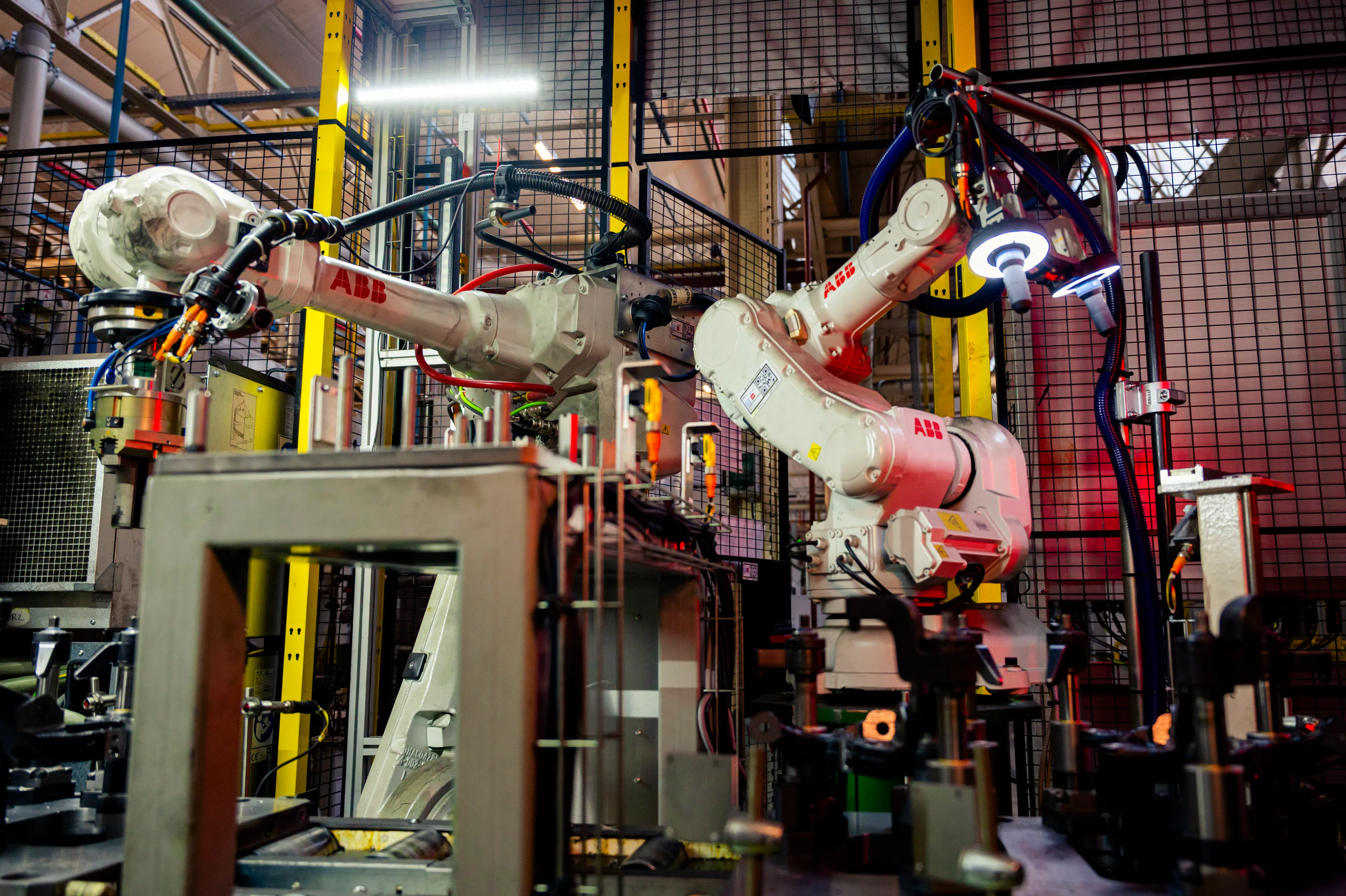

In the 1980s, robotization took hold and deeply transformed production methods, notably with the Super 5, the first model whose front subframe was fully welded by robots at the Le Mans site.

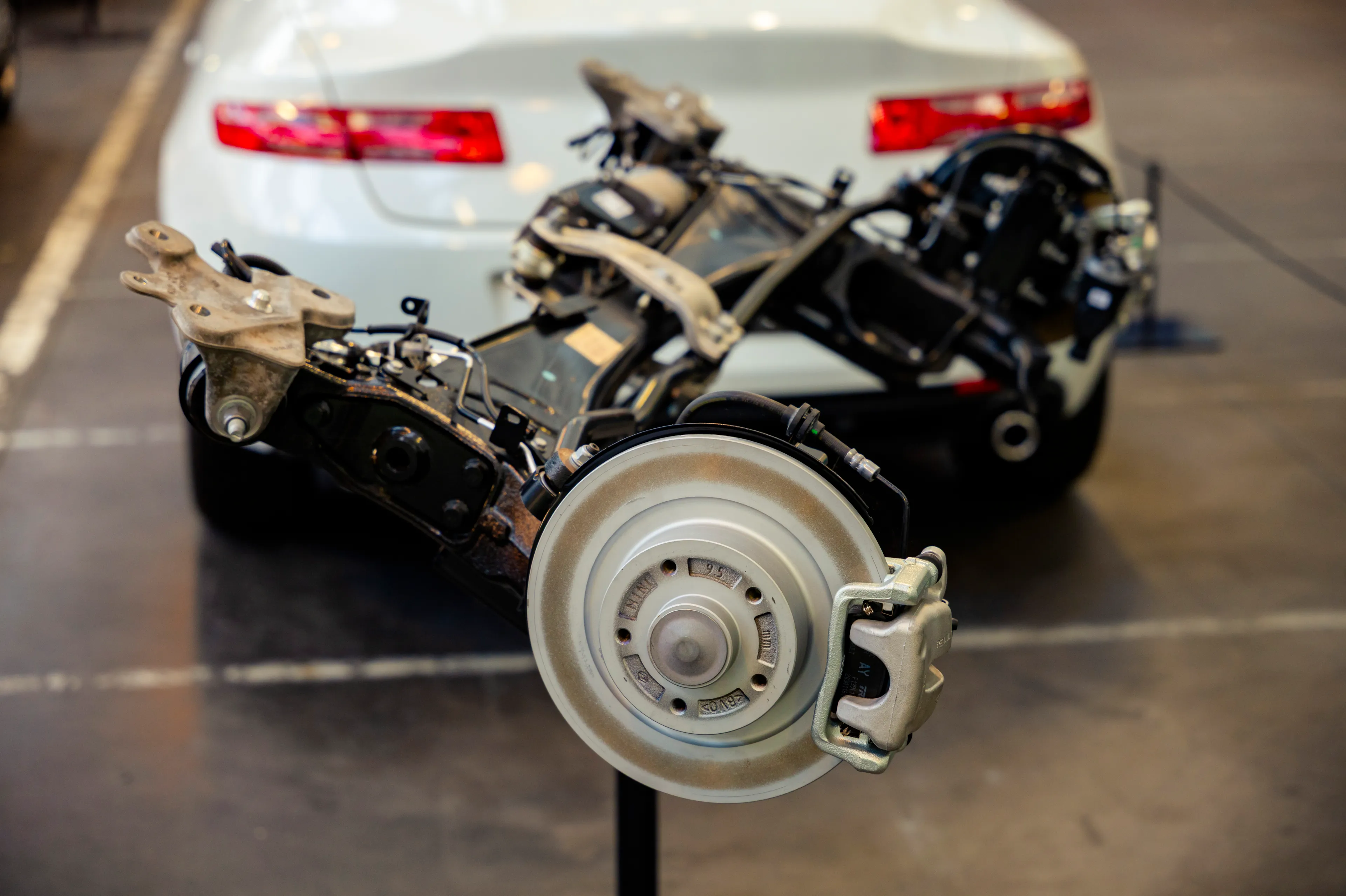

Later on, the Laguna III Coupé introduced an innovative active rear axle with four-wheel steering, illustrating the evolution of the chassis toward increasingly dynamic technology.

These innovations strengthened the Group’s reputation for vehicle handling and contributed to its international recognition.

For flawless road handling, engineering and production work side by side

What sets Le Mans apart is the way professions intersect. Within a single perimeter, engineering designs, prototyping teams build, test teams validate, production engineering industrializes and the factory manufactures. Few sites benefit from such an integrated cycle, and no other manufacturer has brought together its capabilities in this way for something as essential to a vehicle as the chassis.

The figures give a sense of the strength of this ecosystem: around 300 employees in engineering, 1,500 in production, and an industrial setup that includes a foundry, a stamping workshop and 111 automated lines, achieving an annual output of 6.5 million rotors (brake discs and drums, wheel hubs), 1.3 million axles and 1.3 million subframes.

The foundry, integrated into the site and fully automated, operates in a circular-economy model, with short-loop recycling of stamping offcuts and machining chips.

With the digital transformation of the 2010s, modernization accelerated, bringing numerous innovations such as::

- Robots capable of sorting bulk parts using 3D vision;

- Artificial Intelligence (AI)-assisted inspections that instantly detect and analyze production deviations;

- Virtual reality to simulate workstations before they are installed;

- Laser treatment of discs, or laser cladding, a technology that prepares brake discs to meet future Euro7 standards.

These tools enhance human expertise, allowing gestures to be refined, reducing certain physical constraints and improving product quality, and therefore the safety and comfort of end customers.

In the age of electric vehicles, expertise that evolves… while remaining true to its roots

The arrival of electric platforms required a complete rethink of how a chassis is designed. Batteries alter mass distribution, forces shift and the architecture must evolve. The Le Mans industrial site was involved very early in this transformation, starting with the ZOE.

Today, the teams work on the structural components of all the Group’s electric models: Renault 5, Renault 4, Mégane, Scénic, as well as Alpine models and the new generation of light commercial vehicles.

The challenge is threefold: meeting the technical constraints of new vehicles, supporting the development of active systems and preparing emerging technologies such as steer-by-wire and brake-by-wire systems, or chassis capable of communicating with their environment, all while maintaining the fundamentals of industrial processes, which the site masters perfectly.

The transition is also about skills. Each year, the site welcomes many apprentices and interns and continues to recruit in order to support this evolution. It is a way of keeping alive expertise built over time, now enriched with new tools.

Today, the Le Mans site stands as Renault Group’s chassis expertise center. This expertise supports the transition to electric mobility and new technologies, a shift that improves, adjusts, strengthens and continues to evolve a profession at the very heart of the Group’s vehicle handling performance.

Stay tuned for a closer look at the technologies and innovations implemented in Le Mans, from digital tools to next-generation industrial processes.

FAQ – Le Mans’s chassis expertise

What makes Renault Group’s Le Mans site a chassis expertise center?

It brings together engineering, prototyping, testing and production in one place, offering unique continuity between design and industrialization. This proximity enhances quality and responsiveness in chassis projects as well as industrial performance.

The site gathers a wide variety of professions, both within the chassis technical center (design, calculation, prototyping and testing) and in the factory, which includes experts in foundry, machining, stamping, welding, cataphoresis and assembly. Their physical proximity facilitates exchanges and enables faster validation of technical solutions. This is one of the strengths that explains Le Mans’ reputation in chassis expertise.

The site designs, validates and industrializes the chassis components for the Group’s electric platforms. It adapts its tools and skills to the specific constraints of electric vehicles, particularly in terms of rigidity, weight and integration of electronic systems.