All about electric motors with no rare earths

Published on

A historical pioneer in the complex technology of electric motors without magnets, i.e. with no rare earths, Renault Group is continuing to set itself apart on a market where 90% of electric cars have motors with magnets. Discover the range of electric motors by Renault Group.

The different types of electric motor

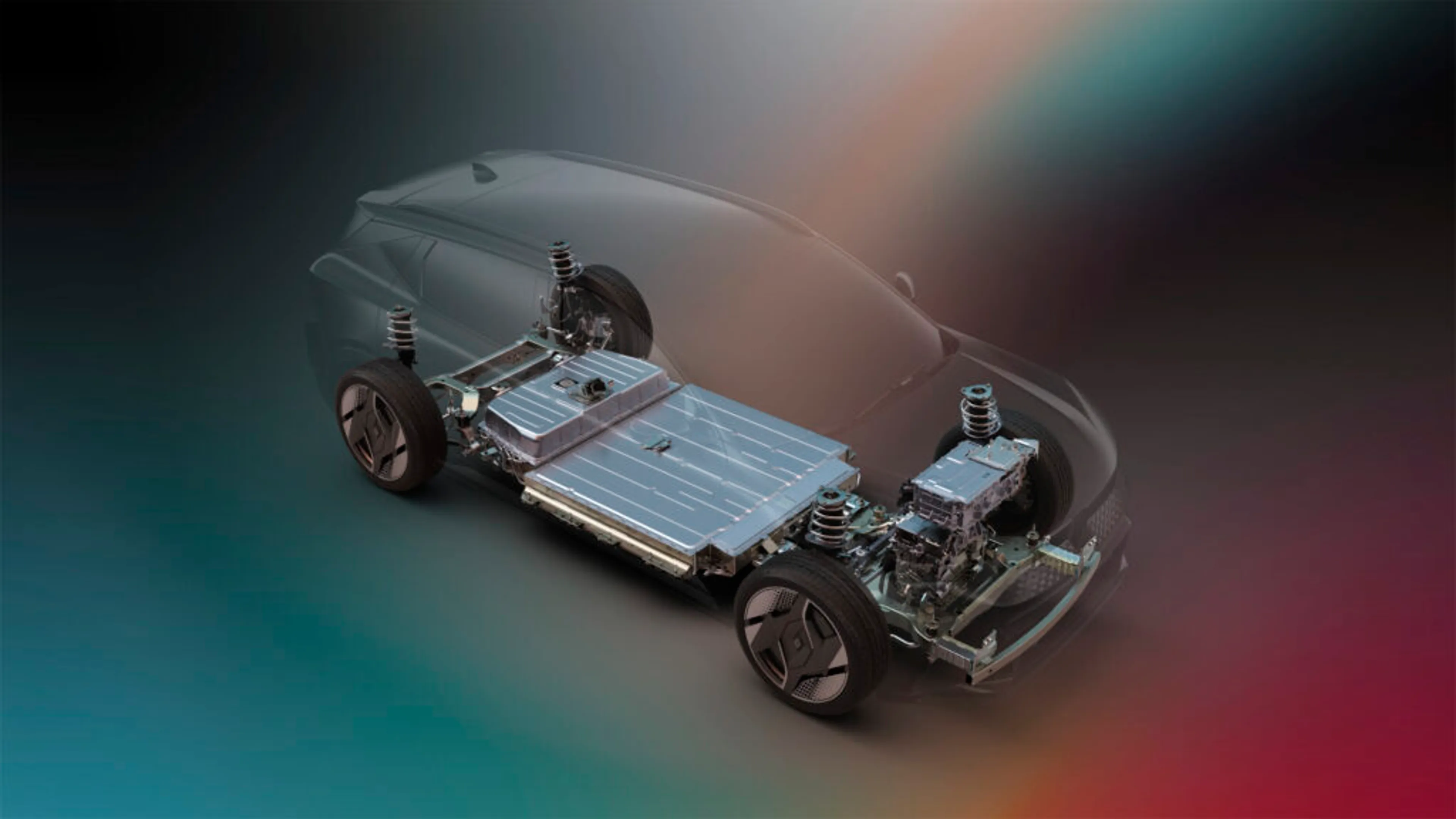

Requiring no piston or cylinders, an electric car motor converts electrical energy from the battery into mechanical energy through a magnetic field generated by the current on the stationary component of the system [stator]. This sets the rotating component [rotor] in motion in order to drive the vehicle's wheels.

We can make a distinction between three main families of electric motors, with significant technical differences:

- permanent-magnet synchronous motors, made with rare earths. This is the dominant technology in the automotive market today. It combines high levels of efficiency with an optimised space requirement.

- asynchronous motors (ASM) also referred to as asynchronous induction motors (IM). Owing to its lower level of efficiency, this technology is now generally used for secondary motors on the front axle.

- electrically excited synchronous motors (EESM). These slightly bigger motors deliver high levels of efficiency without a magnet. These electric motors use no rare earths.

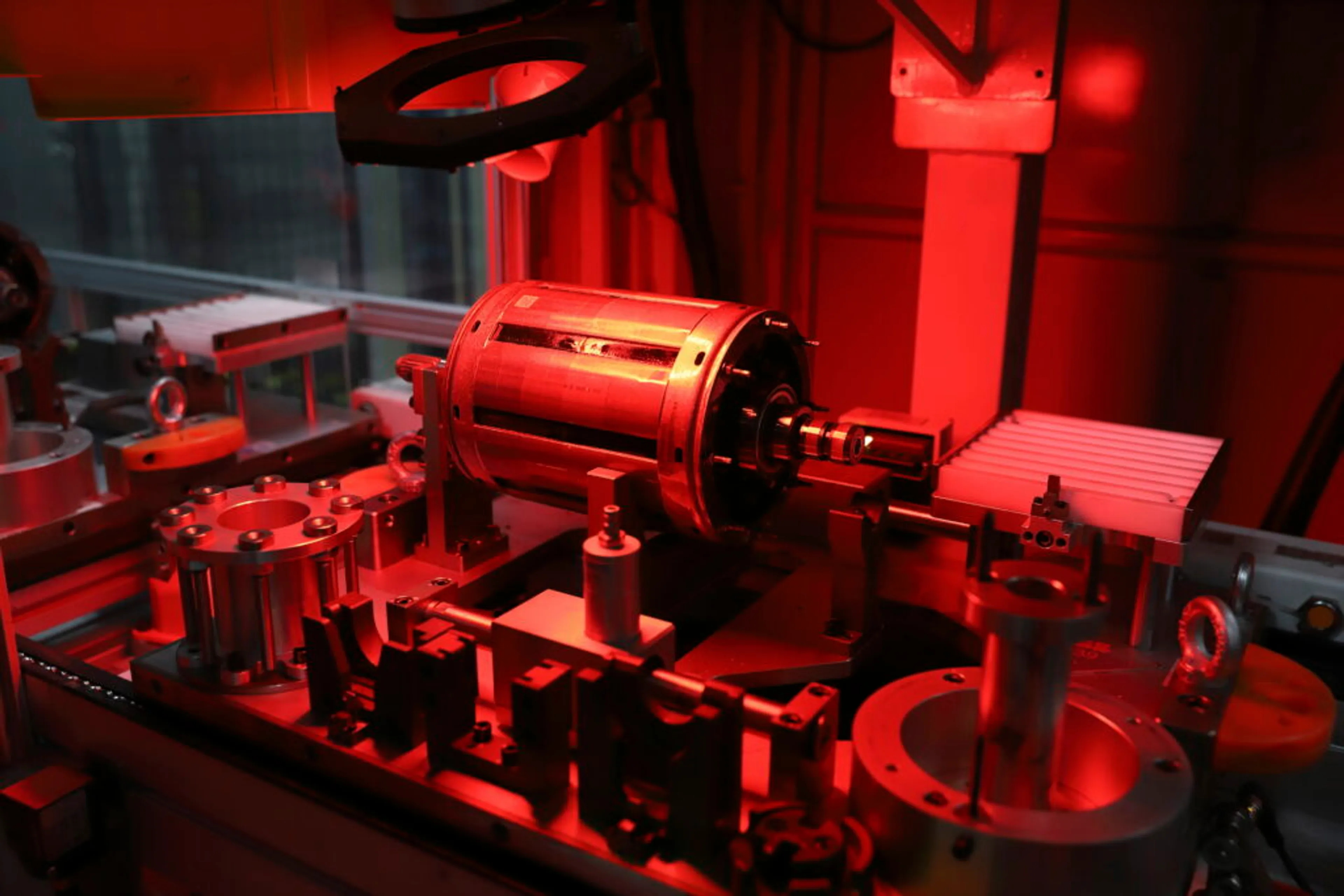

In 2012, Renault Group began the mass selling of EESM electric motors (for Electrically Excited Synchronous Motors) . The result of this unique expertise is a competitive range of electric motors.

Renault Group's range of all-electric motors

A pioneer in electric cars since 2011, Renault Group has made the bold and visionary choice to mass-market EESM technology.

The very first generation of motors was found under the bonnet of Renault Kangoo Z.E in 2011 and Renault Zoe in 2012. Carrying the part reference 5A, it had output ranging from 57 to 100 kW.

In 2020, the final upgrade of this powertrain arrived on Twingo Electric with the reference 5AL and output of 60 kW.

Renault Group's second-generation EESM motor came into production in 2021 with the reference 6A. Renault Megane E-Tech electric was the first model to ship with the new motor (reference 6AM), which was smaller, lighter and more powerful (up to 160 kW), in early 2022. It was followed by the Car of the Year 2024, Renault Scenic E-Tech Electric and most recently the first all-electric Alpine, Alpine A290.

Launched in October 2024 and Car of the Year 2025 Renault 5 E-Tech electric ships with a 6AK electric motor with output of 110 kW, as does Renault 4 E-Tech electric, available to order since March 2025. Alpine A390 features a totally innovative powertrain, unveiled in September 2025. It features a 6AM electric motor on the front axle (like Alpine 290) and a new twin-motor set-up on the rear axle. These three electric motors, all manufactured at Cléon have an estimated combined output of around 345 kw (approx. 470 ch).

The next generation of all-electric EESM motors in 2027

In 2021, Renault Group engineers began working on the third generation of EESM-type electric motors called E7A. Although the development phase is still under way, the specifications are already frozen:

- output of 200 kW, or around 270 hp, for torque of 400 Nm

- a motor that is 30% smaller than previous-generation motors, with its all-in-one architecture

- carbon impact reduced by 30%

- efficiency of around 92%

This electric motor will also cut charging times since the system voltage will be increased to 800 volts, compared with the 400 volt architecture that is currently standard in the Renault range.

A motor with no rare earths: a challenge that is even more strategic than before

By opting for a wound rotor rather than permanent magnets, Renault Group is seeking to avoid reliance on the countries that produce rare earths and magnets.

The presence or absence of rare earths in an electric motor is not a detail but a strategic issue. China produces 85% of the purified light rare earths used worldwide, and 100% of the heavy rare earths. Today, China rarely offers these raw materials for sale. It gives priority to its domestic market and products of higher added value, such as permanent magnets. As a result, it has an almost total monopoly: over 90% of global production comes from China.

At the same time, China is also the world's leading producer of electric cars...

Cléon, the Group's electric motor plant

The Cléon plant has built Renault Group powertrains since 2015. This was when it began making the electric motors for Renault Zoe, Twingo ZE, Kangoo ZE and Master ZE. The motors for Megane E-Tech electric, Scenic E-Tech electric, Alpine A290, Renault 5 E-Tech electric and Renault 4 E-Tech electric are all produced here. From 2027, the Cléon plant will build the new-generation 200 kW electric motor.