The circular economy of electric vehicle batteries

Published on

In response to economic, ecological, and sovereignty challenges facing the automotive industry, Renault Group applies circular economy principles to electric vehicle batteries by extending their first life in vehicles as much as possible, giving them a second life whenever feasible, and finally recycling them in a closed loop to produce new batteries.

Extending battery lifespan: an economic and ecological imperative

Renault Group’s electric vehicles use lithium-ion batteries, which contain so-called “strategic” metals essential to energy performance and the transition to low-carbon mobility. Although these materials play a key role in low-carbon technologies, their availability remains limited in Europe, reinforcing the need for optimized usage.

Surging demand for batteries

Strategic metals such as lithium, cobalt, and nickel are experiencing soaring demand due to the planned increase in electric vehicle sales, as well as batteries for portable devices and soft mobility solutions.

Supply has already been under strain for several years. The International Energy Agency (IEA) highlighted in its latest report on strategic materials (May 2025) that battery material demand could triple to sixfold by 2040, driven by the rise of electric vehicles, soft mobility, and portable equipment.

This is compounded by the high cost of batteries, which can account for up to one-third of an electric vehicle’s price.

Reducing the carbon footprint of batteries

Extending battery life and designing more responsible models is also an ecological necessity aligned with Renault Group’s decarbonization strategy.

The company has formed several partnerships to source low-carbon battery materials within Europe, such as with Terrafame for nickel in Finland and Arverne for lithium in France, with production expected to begin in 2030.

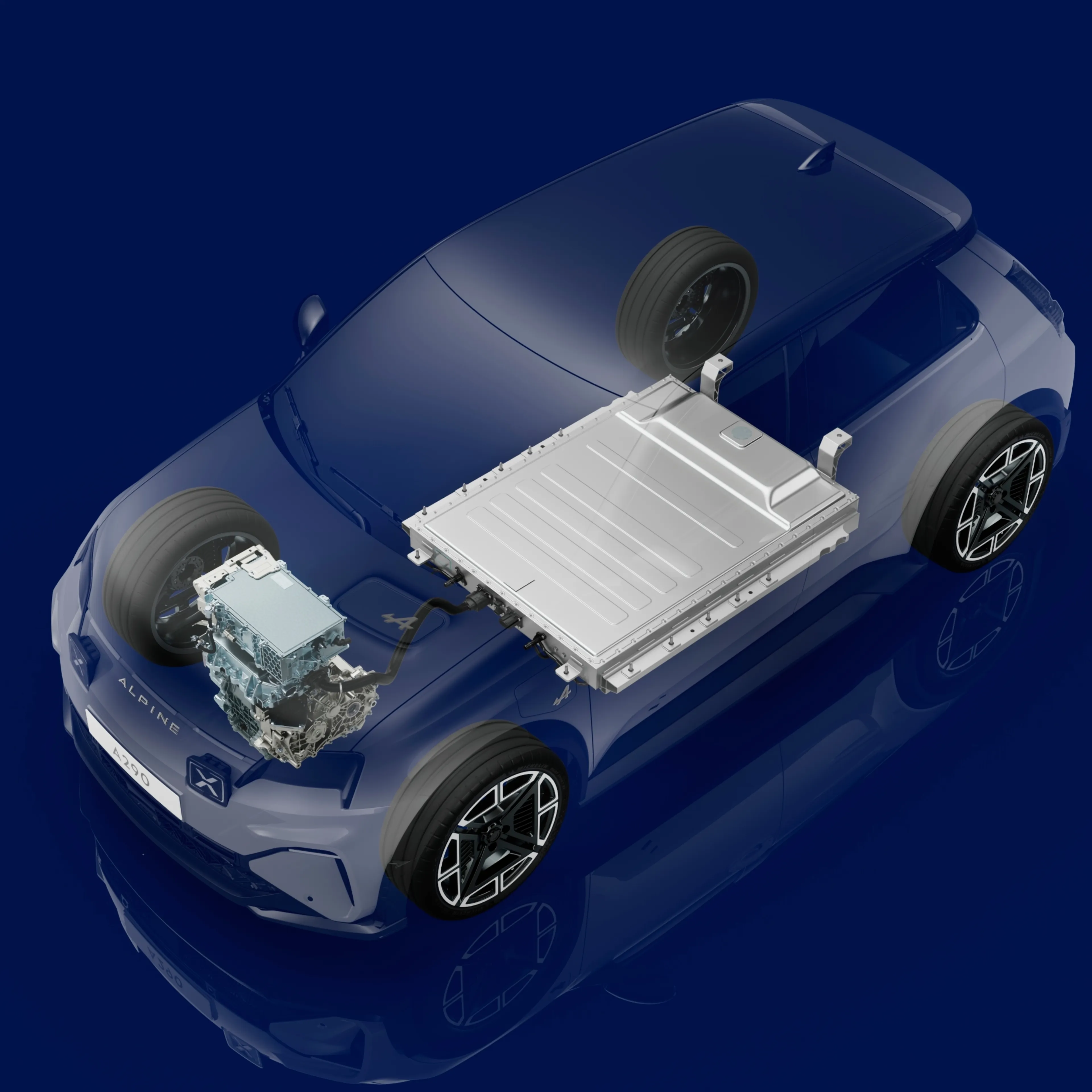

The battery’s first life aboard electric cars

Renault Group’s electric vehicles are equipped with lithium-ion batteries that last at least 10 years, depending on usage. This has been demonstrated by first-generation ZOE models, still on the road after 13 years. Moreover, the Renault 5 E-Tech electric battery will retain over 90% health after ten years*, even when using “Vehicle to Grid” technology, which allows the car to sell energy back to the grid.

*based on the assumption of driving 20,000 km per year

If a battery fails during its automotive life, its lifespan can be extended through repair. Renault Group relies on a European network of repair centers and its circular economy entity, The Future Is NEUTRAL, particularly its subsidiary Gaia, which developed the Battery Repair Expert Center (CERBF) in Flins, part of the company’s circular economy industrial site, the Refactory.

According to Gaia, 99% of batteries processed at CERBF are repairable. Gaia also prepares batteries that have reached the end of their first life for a second life.

Second Life: Reuse Before Recycling

The battery’s life doesn’t end there. Contrary to popular belief, a battery can still retain up to 70% of its energy storage capacity after its automotive life.

After this first life, batteries can be reused in less demanding applications such as micro-mobility solutions or stationary energy storage. Storing energy is crucial for redistributing it during peak consumption periods. These solutions also help offset the limitations of renewable energy sources like wind and solar, which depend on weather conditions.

Battery Recycling

Once it reaches the end of its life, the electric vehicle battery enters its final chapter: recycling.

Closed-Loop Recycling

For over 12 years, since the launch of its first lithium-ion electric vehicles, Renault Group has ensured the collection and recycling of all its batteries.

With the new European Extended Producer Responsibility (EPR) regulation taking effect in August 2025, Renault Group is strengthening its strategy to meet growing environmental and regulatory demands.

EPR now requires automakers to fund collection, ensure traceability, and actively contribute to lithium-ion battery recycling. These obligations are part of an ambitious European framework with increasingly strict recycling targets: 50% lithium by 2027, 80% by 2031, and up to 95% for metals like cobalt, nickel, and copper.

To meet these requirements, Renault Group relies on its subsidiary The Future Is NEUTRAL, which oversees all necessary operations:

- Batteries from end-of-life vehicles (ELVs) are first removed following precise procedures ensuring quality and safety.

- These operations are carried out either by dealerships or ELV centers, particularly those in the Indra network, France’s leading ELV treatment network and a subsidiary of The Future Is NEUTRAL.

- Batteries are then sent to specialized partner channels where they are dismantled, sorted, and recycled according to the tightened European regulations.

- The Future Is NEUTRAL also collaborates with partners to develop a European closed-loop battery recycling sector, aiming for a purity level of recycled metals sufficient to reintegrate them into new batteries, as required by regulations starting in 2031