A journey to the heart of the Group’s chassis innovations

Published on

Building on our previous article devoted to the Le Mans chassis expertise center and its rich history, it is now time to focus on the innovations in which the site is involved. Here, mechanical tradition blends with virtual reality, artificial intelligence, laser processing, robotics, connectivity, and even ‘by-wire’ systems. Six flagship innovations are reshaping the relationship between technology, industry and mobility. They show that the future of the automotive chassis is already being written right here.

In Le Mans, chassis expertise is not just an industrial legacy, it is a constant driving force. For decades, teams have learned to anticipate future uses, develop unprecedented solutions and embrace every technological shift as a natural step forward. Today, the site has reached a new milestone, with numerous solutions built around a single idea: making vehicles safer, more sustainable and smarter. Here is a quick overview of the innovations that are profoundly transforming vehicle chassis systems for the benefit of the customer.

Automated bulk sorting, bringing order to disorder

This is one of the most tangible innovations on the shop floor. Where bins filled with loose parts once required strenuous handling operations for operators, a new robotic cell now uses 3D vision and trajectory-calculation algorithms to accurately pick up each part, regardless of its orientation.

“Automated bulk sorting is a concrete breakthrough: it replaces very strenuous tasks while ensuring both quality and production pace.”

Julien Burgaud

Automation expert

Automated bulk sorting is an innovation that, when deployed on the lower suspension arm production line, reduces operator strain, streamlines production and opens the door to numerous future automation opportunities.

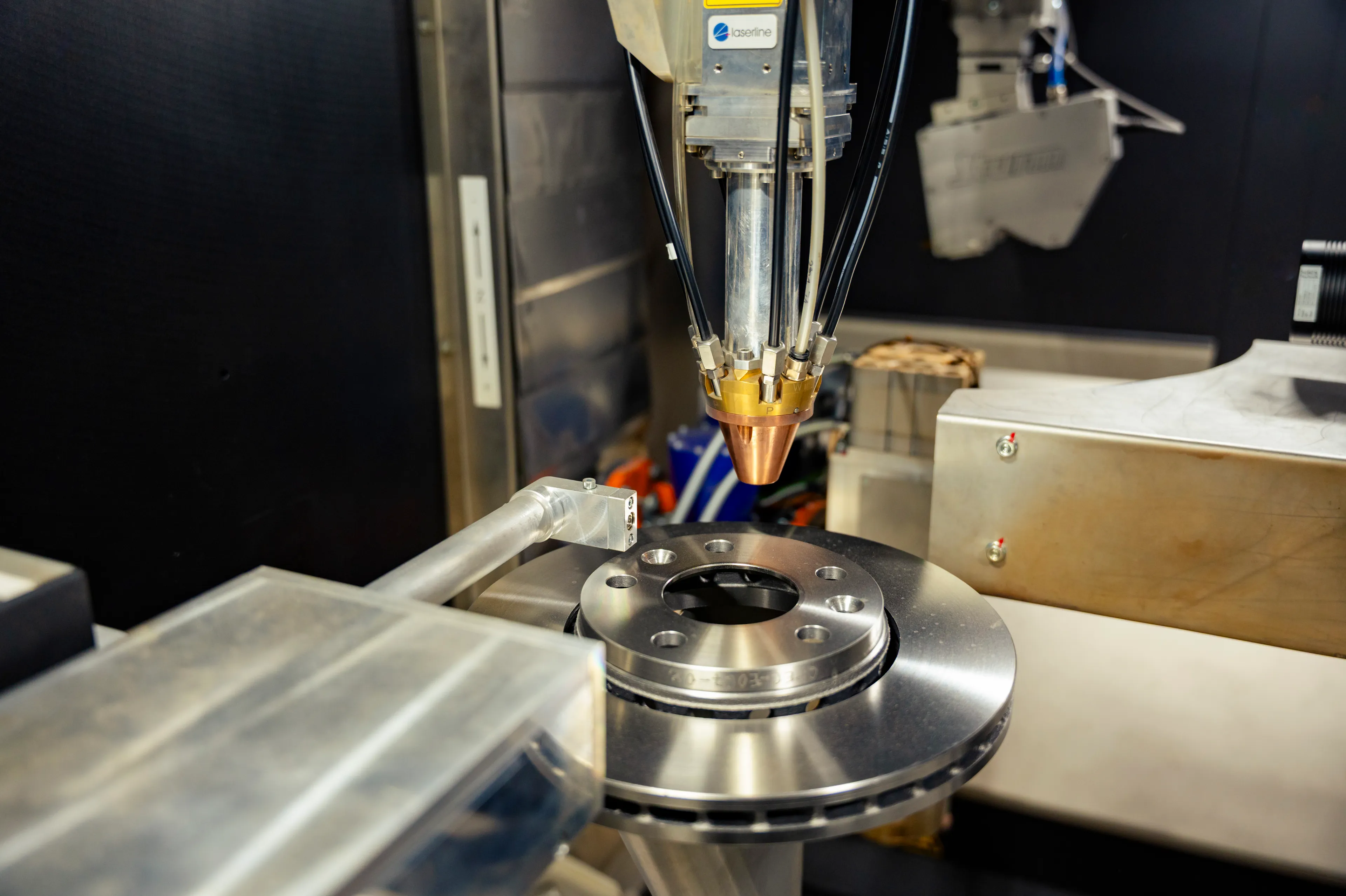

Laser cladding for a new-generation brake disc

To improve braking quality and its associated safety, Le Mans has deployed an advanced laser deposition technology on brake discs: laser cladding.

The principle is simple to explain but complex to master: a highly resistant material is projected onto the surface of the brake disc and then fused using a laser torch. The result is an ultra-robust and durable coating.

“The core of the innovation lies in this laser torch, which fuses a hard material onto the disc surface. The result: braking performance that is just as effective, but far more durable and environmentally friendly.”

Stéphane Carval

Chassis process expert

With laser cladding technology, particle emissions generated during braking are reduced fourfold and the lifespan of the brake discs is significantly extended. A pilot line has been operating at the Le Mans site since 2024 and has already produced 3,000 prototypes, ahead of upcoming mass production.

Virtual reality to understand every detail of the manufacturing process

Far more than a gadget or a secondary tool, virtual reality has become an essential step for major industrial projects in Le Mans. Thanks to the digital twin, teams can immerse themselves in a production line… even before it exists.

They use it to test movements, ergonomics, operator flow, component accessibility and even maintenance interventions.

“Virtual reality allows us to rethink our industrial projects. Even before a line is installed, we can test, adjust and validate working conditions in a realistic environment. It is a practical tool that enhances the safety and ergonomics of our teams.”

Nicolas Hée

Head of Maintenance & Digital engineering

The result: anticipated adjustments, safer workstations from day one and significantly reduced implementation times.

With AI-assisted machining control, precision down to the micron

If this innovation had to be summed up in a few words: when the human eye reaches its limits, artificial intelligence takes over. Thanks to advanced analysis models, the machines in Le Mans can now detect machining micro-anomalies in real time: shape variations, dimensional drift, defects invisible to the naked eye. An essential aid for a production line running 24/7.

“Artificial intelligence does not replace our teams’ expertise, it enhances it. At Le Mans, we use technology to free up time, secure operations and ensure flawless quality. Above all, it is a human-centered innovation.”

Camille Blandel

AI machining control project engineer

With these smart cameras, robots and in-house-developed AI models, ‘material integrity’ inspections gain in precision, reliability and traceability.

APACHE, when the vehicle becomes an intelligent sensor

APACHE stands for Appraisal of Pavement Acoustic CHaracteristics and Energy efficience. But above all, it is a project that turns each vehicle into an acoustic sensor of road conditions. Thanks to data collected in real driving situations, engineers can adjust chassis design parameters, anticipate constraints and optimize durability.

“Creating silence inside the vehicle is good. Creating it outside as well is even better. With APACHE, we turn noise into useful data and put technology at the service of the greater good.”

Thomas Antoine

Noise & vibration lead expert

A patented innovation by Renault Group, APACHE relies on a module that uses the acoustic sensors already present in vehicles equipped with active noise control. The car thus becomes a mobile probe capable of measuring road roughness and acoustic profiles. In other words: the road speaks, and it has become one of engineering’s greatest allies. Le Mans Métropole has even chosen to join the initiative to collect sound-profile maps of local roads and help prioritize infrastructure investments.

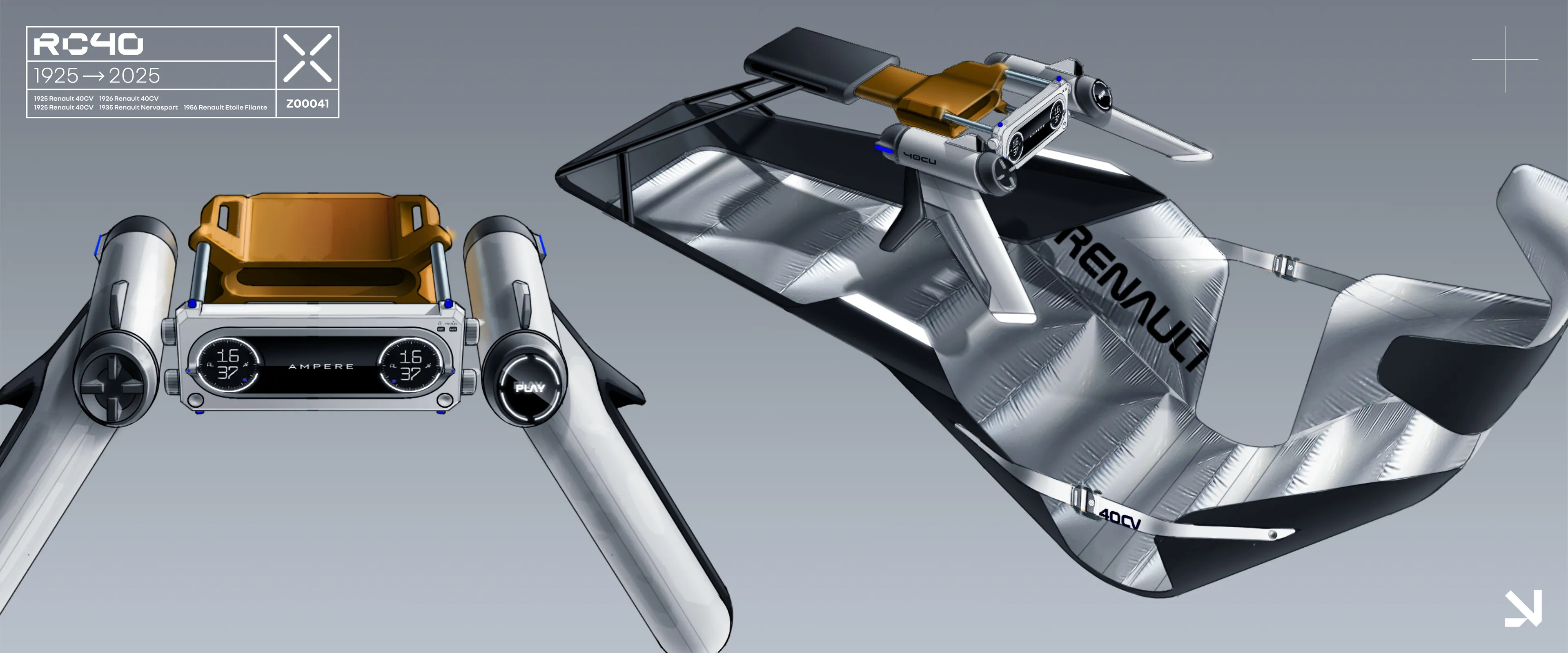

‘By-wire’ chassis systems, where mechanical links give way to electronic controls

This is likely the most spectacular transformation: steer-by-wire and brake-by-wire systems, with no direct mechanical connection to the steering wheel or brake pedal. The driver’s actions are interpreted through electronic signals, enabling a new level of precision, dynamic adjustments and unprecedented possibilities in terms of safety and comfort.

“By-wire chassis technology is redefining the relationship between the driver and the vehicle. Without any mechanical linkage, we achieve remarkably precise dynamic control, unmatched safety and new freedom in design. It marks the beginning of an era in which the vehicle’s chassis becomes intelligent and adaptable.”

David Toffin

Chassis innovation manager

Tested notably on the Filante Record 2025 demo car, ‘by-wire’ technology is preparing vehicles for new uses: advanced assistance, autonomous driving and personalized on-road behavior…

Chassis innovations built to last

Each innovation tells the same story: a desire to go further. Connectivity and active systems are inventing new ways for our customers to interact with the road. Virtual reality and digital twins are transforming the design of industrial tools. AI and robotics (automated bulk sorting, laser cladding, etc.) are reshaping production.

At the Le Mans site, innovation in automotive chassis design is not a break from the past. It is the natural evolution of a technical heritage that has, for decades, shaped the behavior of Renault Group vehicles all around the world.