FOUNDED IN: 1952

LEGAL FORM AND CAPITAL OWNERSHIP: “S.N.C.” (general partnership) with capital of €14,818,044 fully owned by Renault SAS (France)

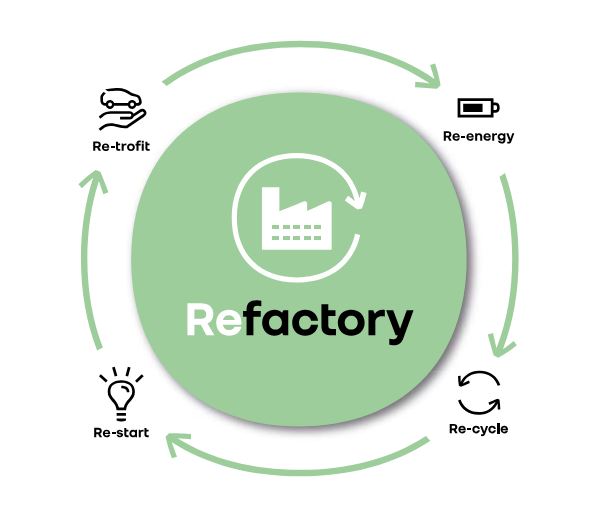

ACTIVITY: Circular economy

WORKFORCE: 1,941 at December 31, 2023

AREA: 232ha, o/w 65 ha of covered buildings

CERTIFICATIONS: ISO 14001, ISO 9001

Activities

RE-TROFIT

The renew factory & The bodyshop factory : Renovate or repair used vehicles to extend their lifespan.

LCV Retrofit: converting thermal Masters to electric.

RE-ENERGY

Using second-life batteries for new applications.

HYVIA: Developing hydrogen-powered mobility solutions.

RE-CYCLE

THE REMAKERS : Renovate parts for re-use in closed loops.

GAIA : Recycling raw materials, reusing parts, repairing batteries.

RE-START

Campus: Promoting research and training on the circular economy.

Open innovation hub: supporting innovative startups in the sector.

Environment

The Refactory in Flins is part of the Group's sustainable development policy and is committed to ensure, through continuous progress, that its activities are carried out in an environmental-friendly manner. The environment is a key issue for the site, in line with the sites decarbonation strategy, being fully involved in the prevention and the management of environmental risks.

Quality

The Refactory is at the heart of Renault Group's circular economy strategy. In a market that is in the throes of restructuring, with increasing regulatory requirements, the Refactory must be exemplary in the quality of its activities.

- 1952: creation of the Flins plant.

- 1956: manufacturing of the Dauphine model begins.

- 1961: manufacturing of the Renault 4 model begins.

- 1972: manufacturing of the Renault 5 model begins.

- 1978: manufacturing of the Renault 18 model begins.

- 1984: manufacturing of the Supercinq model begins.

- 1990: manufacturing of Clio begins.

- 1993: manufacturing of Twingo begins.

- 1994: manufacturing of Twingo (collection 2) begins, featuring the first application of the Easy system [manual gearbox with no clutch pedal].

- 1998: manufacturing of Clio II and Twingo phase 2 begins.

- 2006: 2 millionth Twingo.

- 2012: launch of New Clio and ZOE production.

- 2016: start of the Nissan Micra production in series.

- 2017: 18 millions of vehicles produced since the plant was founded.

- 2019: start of production of New ZOE

- 2021: Start of the transformation of the plant into a site dedicated to the circular economy

- 2023: Launch of The bodywork factory(repair of damaged vehicles)

- 2024: the Refactory, 100% dedicated to the circular economy

Contact us

Refactory de Flins

BP 203

78410 AUBERGENVILLE

France

+ 33 (0)1 76 82 72 72