A BIT OF HISTORY…

Renault Group and road safety is a story that began more than 60 years ago, when one of the company’s doctors, Dr. Claude Tarrière, set up the accidentology and biomechanics laboratory.Over the decades, while the brand's vehicles have become progressively safer for those on board, they have become increasingly complex, especially for emergency services. In 2010, driven by its commitment to improve safety, Renault Group – through its Corporate Social responsibility Department – decided to work closer with road rescue services in developing ways to better save lives. The notion of tertiary safety, an area focused on making road rescue operations safer, faster, and more efficient, took on full meaning within the group. It is the next logical step after primary safety (all systems that help prevent accidents or reduce their consequences) and secondary safety (everything that protects passengers during an accident).

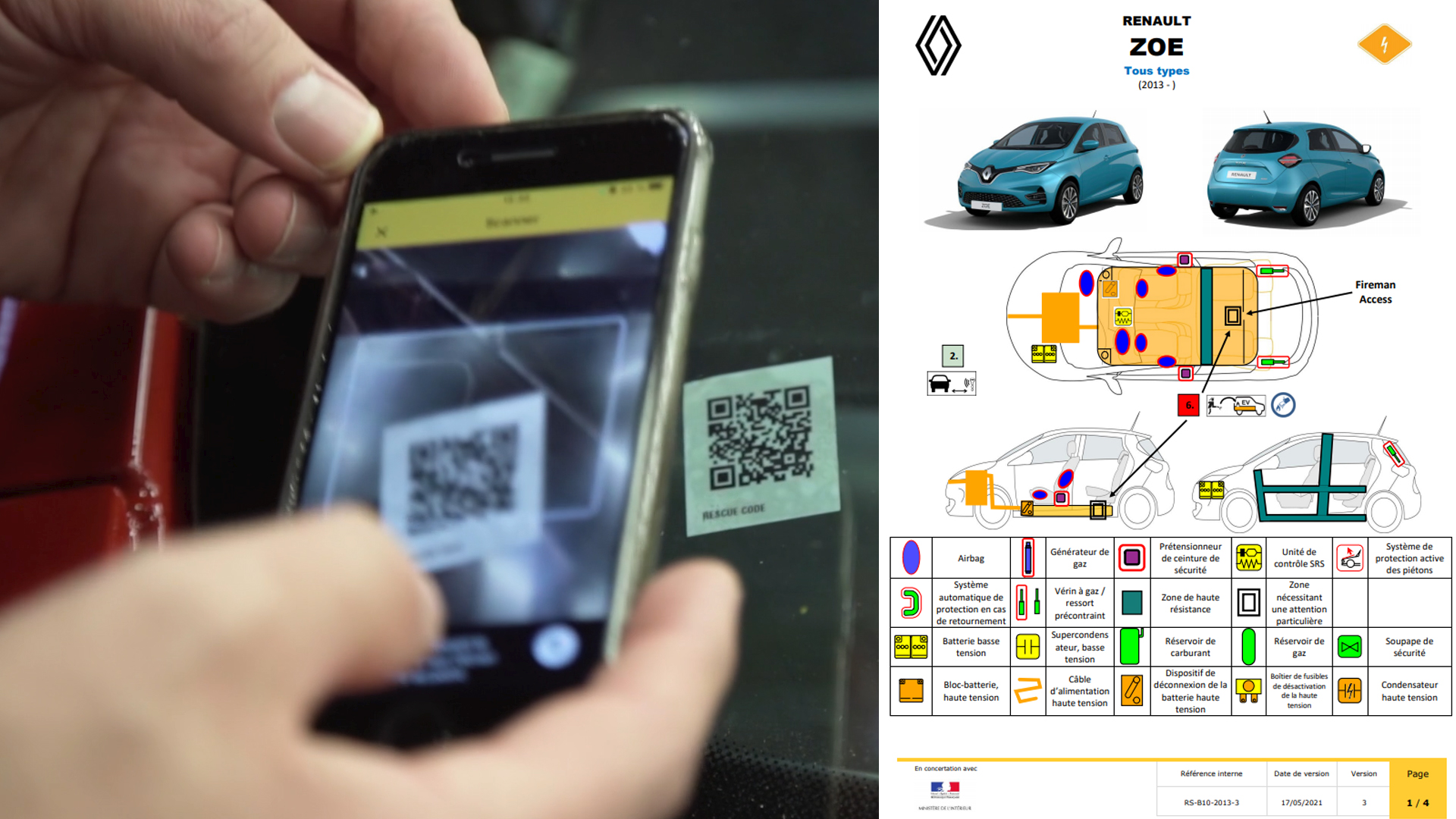

Modern cars are rapidly changing, therefore rescue operations need to adapt in order to keep up. When the first electric vehicles hit the market, Renault Group stepped up collaborative efforts with the fire and rescue services. In turn, rescue services came to see Renault Group as not just a car manufacturer, but also a major ally.

2018 was a major milestone in their shared journey. Christophe Lenglos, a ranking officer from the Yvelines Fire and Rescue Department, was assigned to the Renault Group R&D Technocentre. Since then, Lieutenant-Colonel Lenglos has worked alongside Claire Petit-Boulanger, Tertiary Safety Expert who started out at the CSR division (Corporate Social Responsibility). Since early 2021, the pair has been working with the vehicle safety teams at Engineering.

"Our partnership serves three main purposes.

First, we work with the people in Engineering and vehicle development daily to ensure they are aware of the constraints and needs of emergency services.

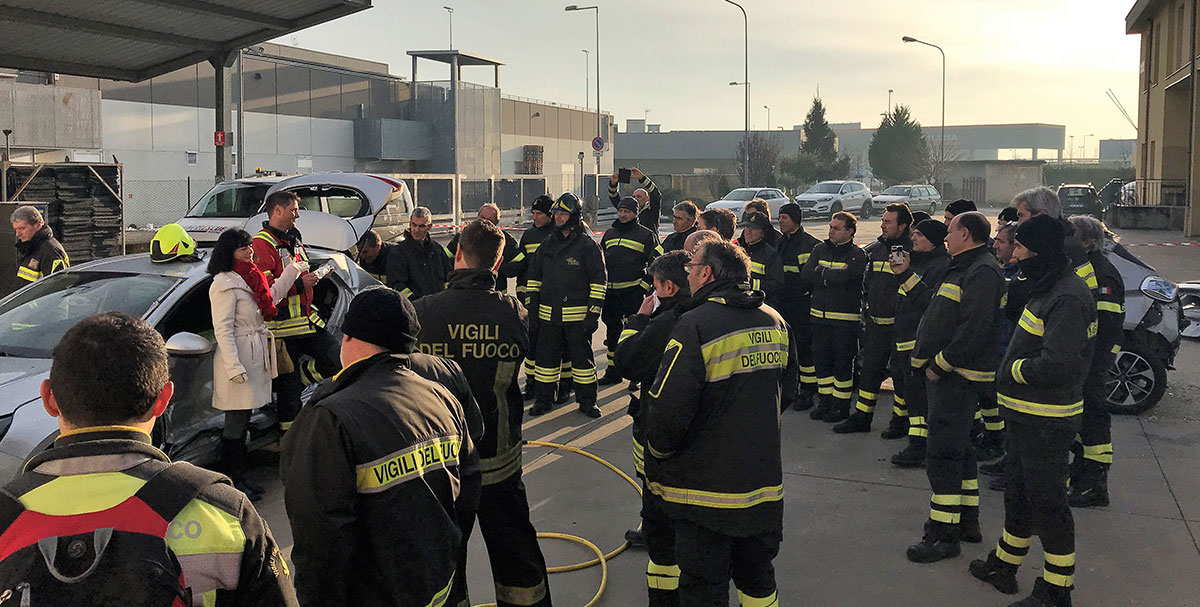

We also take the knowledge that we have acquired within Renault Group and share it with first responders in France and abroad through fire-fighter training sessions.

Lastly, we promote Renault Group’s involvement with emergency workers before the French Ministry of the Interior (DGSCGC) and international organizations (such as World Rescue Organization, International Emergency Firefighters), so that emergency services will have the best possible support when dealing with new vehicles in the future. “

Claire Petit-Boulanger, Tertiary Safety Expert at Renault Group Engineering