The Lardy Technical Center

The Lardy Technical Center, which opened in 1951, handles testing of all Renault engines and gearboxes. In 2011, the centre set up an electric vehicle unit for testing the motors and batteries used in Renault’s ZE lineup.

The site is also responsible for testing vehicle functions, validation of which relies heavily on simulation systems. There are more than a hundred test benches rooting out failure risks in axle and chassis systems, to ensure they’ll go the distance, regardless of road conditions. And body equipment undergoes tough treatment to ensure it’ll stand the test of time, and anything the weather can throw at it in the way of heat, cold, wind and wet.

Lardy also handles the full range of passive safety tests, including front, side and rear collisions. The centre’s test rigs cover most kinds of real-life accident situation, the aim being to improve vehicle resilience and minimize the risk of bodily injury to occupants.

The big crash

That’s precisely where our visit starts, observing the installation of four dummies (two adult-sized ones at the front and two child-sized ones at the rear) in a superb white ZOE, which is set to be propelled against an obstacle at a speed of 65 km/h. Each crash test demands three days of preparation. Here we see the technicians making the final adjustments. The car’s bristling with sensors. The boot’s packed with electronic gear. And paint is being applied on the dummies so that the impact points on the car interior can be determined. Once everything’s ready, everyone scurries off the test track. The car is ready for its last run, a sacrifice that will be everything but futile.

The whirr of the engine ends just seconds later in a mighty crash, followed by total silence: a terrifying sound sequence that brings dread to every motorist’s ear. The car went from 65 km/h to standstill over a distance of 50 centimeters. That works out at a deceleration of 35 G, which is seven times that supported by a fighter pilot. Though the front of the car has been well and truly demolished, the passenger compartment has actually withstood the impact very well. You can even open the doors fairly “normally”, which is quite astounding when you think about it. As passive safety manager Fabien Duboc explains: The idea is to absorb impact energy at the front, keep the passenger compartment intact, and protect the occupants with airbags, seatbelts and force limiters. For example, the airbag inflates just 30 milliseconds after impact. As for the four dummies, well there seems to be very little in the way of major injury. Just minor damage to the driver’s ribcage and left leg, and the passenger’s right leg. Nobody will be spending the night in hospital.

So what about safety considerations specific to this being an electric car? To start with, ZOE’s airbag controller shuts down battery power immediately, so all circuits are dead. There’s no risk of electrocution: even if a battery is intact after an emergency shutdown (as shown in the photo below), it will need reinitializing at a specialist centre.

During the design phase, close to a hundred ZOEs will have undergone all types of crash test (front, side and rear impact, pedestrian impact, etc.).

The 12 trials of ZOE

Our visit continued with a look at the watertightness tests on ZOE. Here we find a black ZOE in a gigantic shower room, which simulates any kind of climate condition, from a misty morning in Brittany through to a Mediterranean thunderstorm or a tropical downpour in the Brazilian rain forest. There’s a hydraulic system for varying the vehicle inclination, while a technician inside the car examines the interior with a torch to detect the slightest leak. This is also the place where they check that ZOE’s charge connector (concealed behind the front badge) can be plugged in with no risk despite the pouring rain outside! The car is checked for leakage under spray from a high-pressure cleaner. And the technicians will also be looking for signs of condensation in the lighting units (bearing in mind that electric vehicles don’t have the same lamp temperature as their internal-combustion counterparts). As Marc Manconot, watertightness validation manager, reminds us, ZOE has also been tested to confirm fault-free operation at a speed of 10 km/h in 40 centimeters of water, which means the battery is submerged. Again, the tests confirm there is no risk of electrocution.

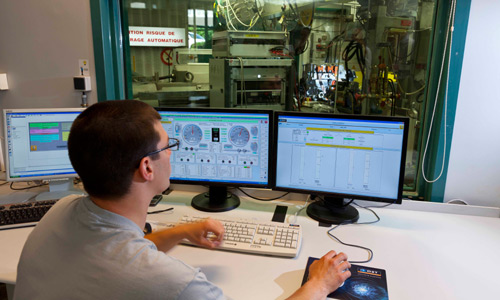

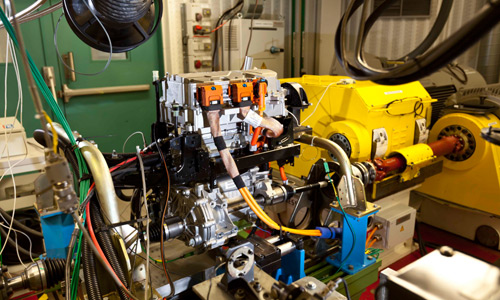

Further along, we find an electric motor test bench running a comprehensive test program that covers electrical tuning, characterization (speed, torque), road cycle simulation and endurance (heat, vibration). Here a “5A generation 2” motor (for ZOE) undergoes the equivalent of 20 years’ normal road use over a period of 8 to 12 weeks, running round-the-clock at temperatures that vary from -20°C to +90°C. An engineer explains that the power electronics system is more important than the powertrain as such, especially as regards cooling”. He also reminds us that “an electric motor has an efficiency of 90%, way above that of the best internal combustion engines, which never exceeds 30% or 40%.

The last stop in our tour is at the battery unit, a 2,500 square meter building that tests the batteries powering Renault’s ZE range, including ZOE. Again, endurance is tested under the harshest conditions. In a climatic chamber fitted with a refrigeration system, a battery pack undergoes the toughest treatment to confirm its lifespan, reliability and performance over time. Then there are the aggression tests: chemical (fire, immersion, combustion), electrical (overload, external short-circuit, loose connection, nail test, etc.) and mechanical (static and dynamic compression, drop, pressure). More than a hundred battery tests will be carried out in 2012, as part of Lardy’s extremely tough schedule for ensuring ZOE will stand up to anything a normal road life might throw at it.

View more

SAFETY: 5 EURO NCAP STARS AND BEST RATING IN ITS CATEGORY FOR THE ALL-NEW CLIO

The All-new Renault CLIO: the most comprehensive driving assistance on the market